Xiamen Meisida: Precision Production & Craftsmanship Unveiled

Xiamen Meisida Accessories Co., Ltd. Showcases Dynamic Production Line in Latest Factory Update

August 22, 2025 — Xiamen Meisida Decoration Co., Ltd., a leading manufacturer in China's decoration industry, recently shared a behind-the-scenes glimpse into its state-of-the-art production facilities, highlighting the dedication of its workforce and the precision of its machinery. The photos, captured across four key production zones, underscore the company's commitment to quality and efficiency in meeting global demand.

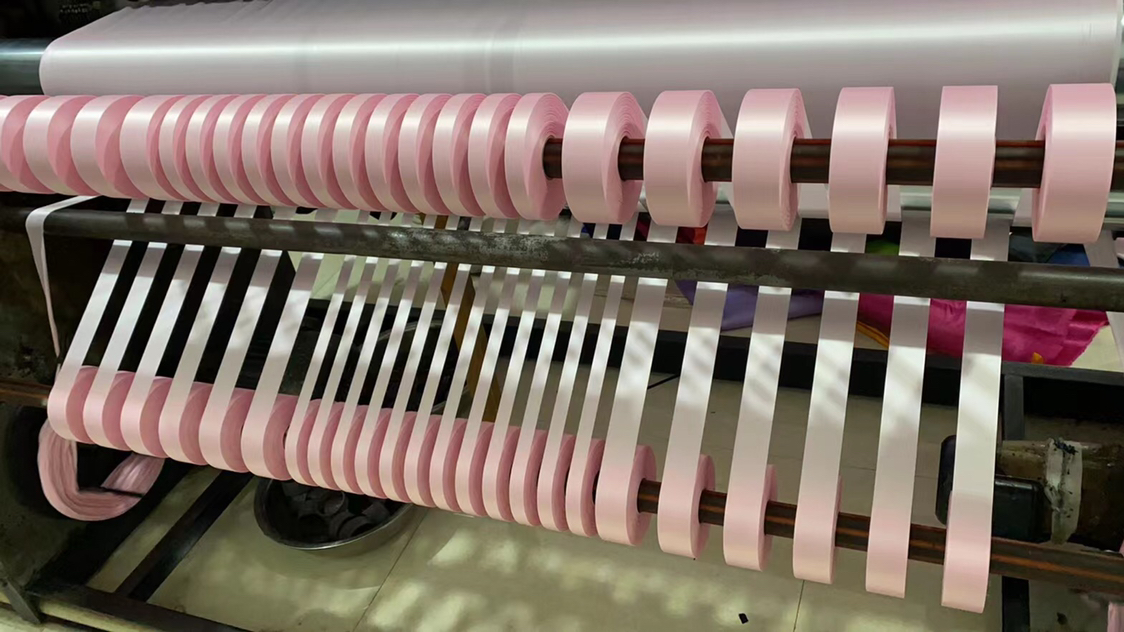

1. Slitting Machine Operation: Precision in Motion

The first image ( ) captures a slitting machine in action, meticulously cutting pink ribbon materials into uniform strips. The automated equipment operates with minimal human intervention, though technicians monitor the process to ensure dimensional accuracy. The orderly workspace, free of debris, reflects the company's emphasis on lean manufacturing and waste reduction.

) captures a slitting machine in action, meticulously cutting pink ribbon materials into uniform strips. The automated equipment operates with minimal human intervention, though technicians monitor the process to ensure dimensional accuracy. The orderly workspace, free of debris, reflects the company's emphasis on lean manufacturing and waste reduction.

2. Metal Fabrication Workstation: Craftsmanship Meets Technology

Contrary to its filename "Manual Printing Station," the second photo ( ) reveals a metal fabrication zone. Workers here employ handheld tools to process gray-black metal sheets, trimming edges and refining surfaces. The workspace features a dedicated "Runway 1" area, where materials are secured for stability during operations. Auxiliary equipment, including material reels and positioning guides, aids in maintaining consistent output.

) reveals a metal fabrication zone. Workers here employ handheld tools to process gray-black metal sheets, trimming edges and refining surfaces. The workspace features a dedicated "Runway 1" area, where materials are secured for stability during operations. Auxiliary equipment, including material reels and positioning guides, aids in maintaining consistent output.

3. Manual Screen Printing: Artistry in Every Stroke

The third image ( ) returns to the company's core competency—screen printing. Workers are seen using silkscreen frames and squeegees to apply blue ink onto fabric substrates. The process involves aligning patterns, flooding the screen with ink, and executing precise strokes to ensure even coverage. Post-printing, materials are transferred via conveyor belts for drying, demonstrating the integration of manual skill and automated workflows.

) returns to the company's core competency—screen printing. Workers are seen using silkscreen frames and squeegees to apply blue ink onto fabric substrates. The process involves aligning patterns, flooding the screen with ink, and executing precise strokes to ensure even coverage. Post-printing, materials are transferred via conveyor belts for drying, demonstrating the integration of manual skill and automated workflows.

4. Warping Machine: Laying the Foundation for Textiles

The final photo ( ) depicts a warping machine, a critical component in textile production. Yarn tensile control systems regulate thread tension as they are wound onto beams, preparing them for weaving. Technicians patrol the equipment, utilizing tension gauges to verify stability. The clean, well-lit environment and organized tool placement highlight the company's adherence to international quality standards.

) depicts a warping machine, a critical component in textile production. Yarn tensile control systems regulate thread tension as they are wound onto beams, preparing them for weaving. Technicians patrol the equipment, utilizing tension gauges to verify stability. The clean, well-lit environment and organized tool placement highlight the company's adherence to international quality standards.

A Symphony of Skill and Innovation

Xiamen Meisida's facilities exemplify the synergy between human expertise and advanced machinery. From slitting ribbons to warping threads, each stage of production is executed with meticulous care. "Our team's dedication ensures every product meets the highest benchmarks," said a plant manager. "Whether it's manual printing or automated metal processing, we prioritize precision and sustainability."

As the company continues to expand its global footprint, these images serve as a testament to its operational excellence and the unwavering commitment of its workforce.

For more updates, visit Xiamen Meisida's official website: https://www.mystyleribbon.com/

- Polypropylene ribbon and bow

- Poly ribbon spool

- Poly ribbon egg

- Poly star bow

- Poly pull bow

- Polypropylene fountain bow

- Ribbon Bow

- Gift Ribbon Bow

- Packaging Ribbon Bow

- Ribbon For Bows

- Garment Ribbon Bow

- Satin Ribbon Bow

- Bottle Ribbon bow