Overseas Production Success Driven by Skill and Technology

Skill and Technology in Harmonious Unity: A Vivid Exploration of Our Overseas Production Triumph

In the global manufacturing landscape, where efficiency and quality often compete, our overseas production hub has found perfect harmony—stitched from skilled hands, cutting-edge technology, and unwavering excellence. Today, we explore three defining snapshots of our facility that capture daily operations and reveal how we’re redefining modern production.

Our first stop: pre-production workstations, where air hums with focus. A team of 12 textile specialists leans over vibrant red fabric, inspecting each yard for consistency before cutting. “This is for our holiday collection,” says lead tech Maria Gonzalez (8 years of experience). “Color must be uniform, weave durable—every fold sets the line’s tone.” One uses a 0.1mm precision cutter; another smooths fabric to erase wrinkles. Nearby, digital pattern templates (adjusted for real-world fabric behavior) bridge planning and craft. It’s old-world detail meets modern precision—proof advanced production starts with care for materials.

Across the 15,000-square-foot facility, we reach the tech-equipped sewing stations. Energy shifts to coordinated motion, as smart machines work alongside skilled sewers. “These aren’t replacements—they’re amplifiers,” says floor manager Carlos Mendez. Machines are programmed with garment-specific stitches; worker Li Wei guides fabric, noting: “Machines handle repetition, but I ensure perfect fit—that’s irreplaceable human touch.” Since integrating the tech six months ago, output is up 25% and errors below 1%—a speed-precision balance keeping us competitive.

A wide view of the full line reveals its magic: rows of calibrated equipment, color-coded to streamline workflow. Prep teams feed cut fabric to bins; sewing passes pieces to pressing; inspectors check for quality under bright lights. “Coordination is key,” Mendez says, noting real-time digital tracking and daily huddles to fix bottlenecks. “Cross-training keeps us agile.” Today, the line fulfills a 5,000-unit retail order—once a week-long task, now on track to ship in 48 hours, thanks to skill and smart setups.

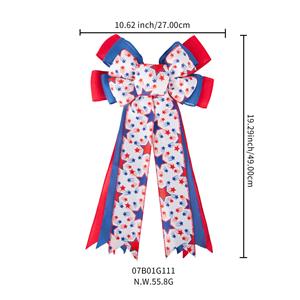

- Polypropylene ribbon and bow

- Poly ribbon spool

- Poly ribbon egg

- Poly star bow

- Poly pull bow

- Polypropylene fountain bow

- Ribbon Bow

- Gift Ribbon Bow

- Packaging Ribbon Bow

- Ribbon For Bows

- Garment Ribbon Bow

- Satin Ribbon Bow

- Bottle Ribbon bow